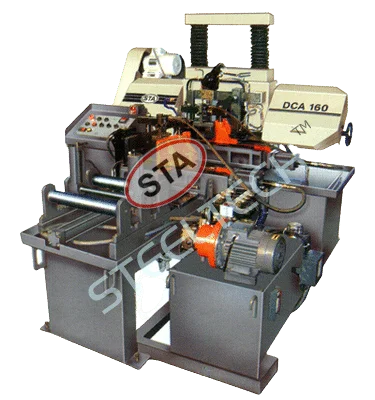

Fully Automatic Double Column Bandsaw Machine

Model - DCA 160

- ✔ Heavy Duty, High Speed

- ✔ High Productivity

- ✔ Large Cross Section of Swing Frame

- ✔ Integral Front & Rear Bed Design

Details

Our company is engaged in the manufacturing of semi-automatic Bandsaw machine, which is used for cutting steel rods. Serving the industries like, automobile industry & automobile vendors, this machine is all set up, but some functions have to be done manually too. The standard specifications can be summarized as follows

Specifications

| Cutting Capacity | ø 160 |

| Blade Size | 3505×27 x 0.9 mm |

| Feed Length | 0-400 mm |

| Drive Motor | 2 HP |

| Hydraulic Motor | 1 HP |

| Coolant Motor | 0.15 H.P |

| Machine Operations | Manual / Hydraulic optional |

Additional Information

Vertical saw Head :

Vartical Saw Head is Supported by two Rigid Induction hardned & Hard Chrome plated & ground columns. Blade tensioning is done by Manual / Hydraulically operated cylinders. Auto Hight sensor optimizes ideal position of blade with least down time.

Saw Feed :

Vartical Saw Head up down motion is controlled by two Hydraulic cylinders. Feed for various material is regulated by temperature & pressure compensated flow control valve. FFC valve is provied to control the cutting pressure required for various types of materials & different tensile strength & BHN.

Clamping :

Clamping of job is done by hydraulically operated vice Jaws. Fixed vice jaws are perpendicular to the blade. The moving vice clamps the job with sufficient work pressure. For tube cutting variable vice pressure will be provied as optional accessories.

Floating Vice Jaws :

To accommodate bend back bars. Floating vice jaw arrangement is provided for shuttle vice. This feature comes only in fully Automatic Double Column Model.

Accuracy :

Taper 0.1 mm for 100 mm. Length ± 0.2 mm

Band Wheels :

Drive & Driven band wheels with optimum centre distance gives smooth blade twisting force which results in excllent performance of blade.

Standard Equipments :

- ■ Complete electrical equipment with panel board, limit switch & electric motors

- ■ Complete hydraulic system with Yuken make DC valve.

- ■ Coolant System with pump and piping.

- ■ Power driven chip brush for easy chip removal from blade.

- ■ One M42 grade bimetal blade.

- ■ Operation tools & spanners.

Optional Equipments :

- ■ Chip Brushes

- ■ Roller table 1500 mm

- ■ Bimetal Bandsaw blade

- ■ Variable vice pressure

- ■ Nesting fixture assembly for bundle cutting up to ø 35 mm polish bars.